Microscopy

Rotary axis for wear testing styli

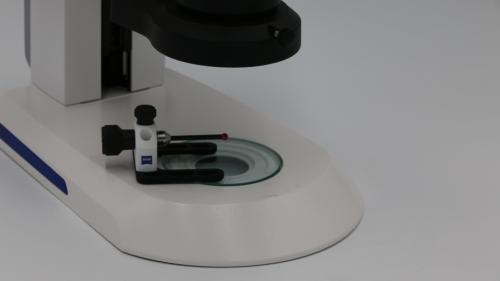

Styli, like manufacturing tools, are subject to natural wear and tear. Probing or scanning can damage or contaminate the measuring elements (e.g. the balls). This wear can adversely affect the measuring accuracy. Therefore, it is recommended to check the measuring elements regularly. The signs of wear are usually not visible to the naked eye. Therefore, at least a magnifying glass, or better a microscope should be used for inspection. For inspection under a microscope, the use of a rotary axis is recommended in order to be able to inspect the complete circumference. Since such rotary axes are usually expensive and equipped with many functionalities that are not required for pure stylus testing, the functionalities of this rotary unit are limited to the most necessary.

- Easy handling

- Can be used on all devices regardless of brand

- Clamping function to fix a position for further examinations

- product type

- Rotary Elements

- Application

- Check

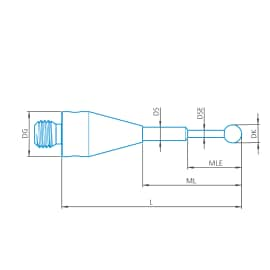

Stainless steel rotary axis, plain bearing guided, operation by knurled knob M5 threaded quick connection in the center screw-on surface Ø20 mm axis height approx. 20 mm Clamping possibility Plastic foot for safe stand

Product note

The rotary axis is equipped with an M5 thread, for testing probes with other threads an appropriate adapter must be used. M5 adapters to smaller threads can be found in the connecting elements section